ELASTO

|

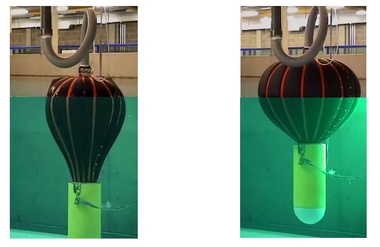

There is potential to reduce the cost of wave energy through use of deformable fabric/elastomeric structures for wave energy conversion. Deformable bodies can have several advantages over their conventional rigid counterparts. In particular, a heaving deformable body can have a longer resonance period than that of a heaving rigid body of the same size, because of lower hydrostatic stiffness. This means that the device can be smaller and hence cheaper if a derformable body is used. Further advantages of fabric/elastomeric structures are that they are lightweight, they do not require as much material as rigid structures for the same given volume, and they have very good fatigue properties.

A flexible WEC is not only potentially smaller and lighter than a comparable rigid device but it does not assume its final volume until it is on-site. This means that transport and deployment costs are also reduced. We will perform a) modelling to understand the performance loads on two devices: one with deformable/elastomeric parts and a rigid counterpart device for comparison, b) some initial materials testing of a promising material that could be used for deformable devices together with the construction of trial fabrication samples and c) a techno-economic study which includes a roadmap for technology development. We aim to prove the principle use of deformable structures in wave energy will lead to improved survivablity and reduced cost without compromising performance. For more information, see here (Wave Energy Scotland). This project has been supported by Wave Energy Scotland

|

Proudly powered by Weebly